Z Aluminum Sections in Construction: Designing for Durability and Aesthetics

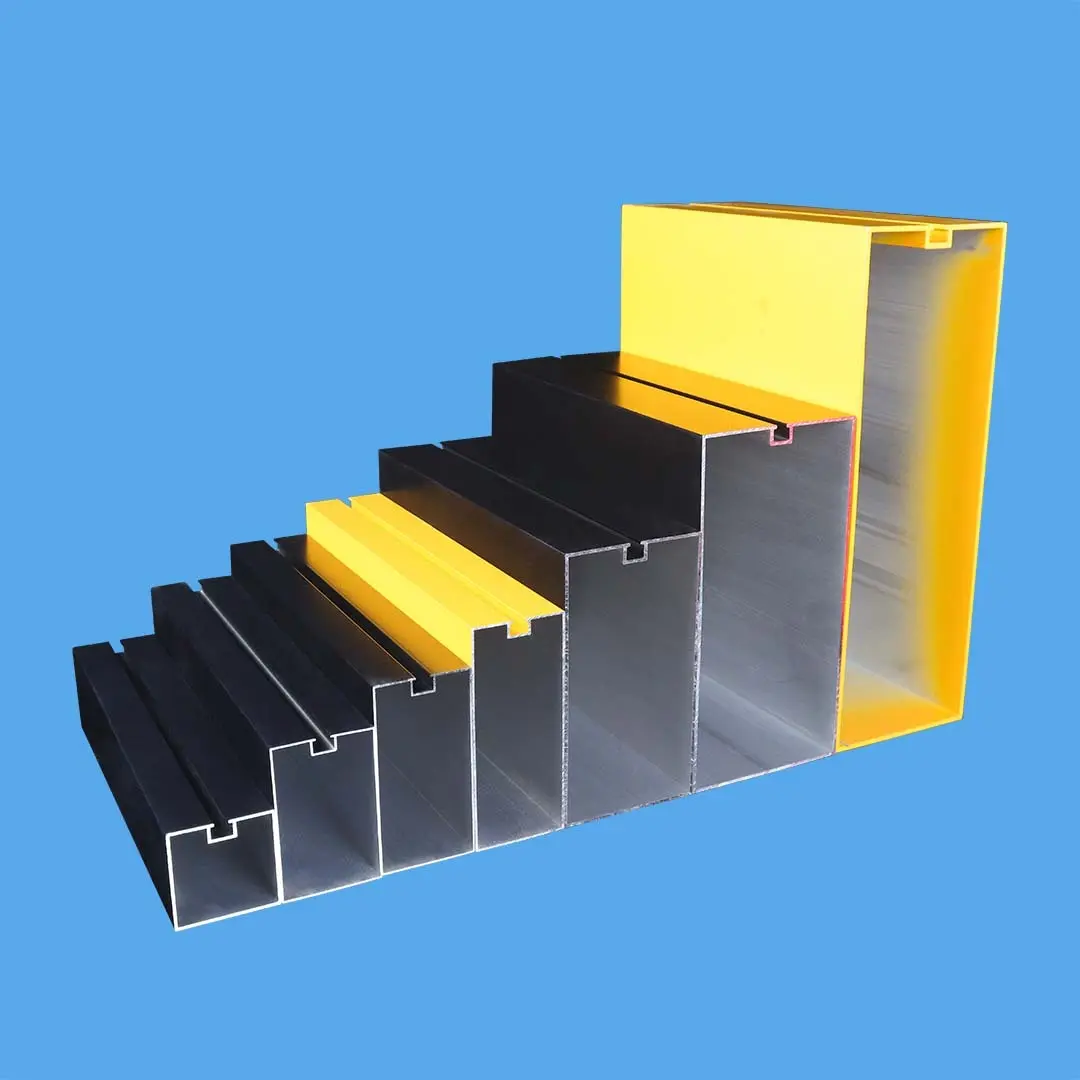

Understanding Z Aluminum Sections: Key Features and CharacteristicsZ aluminum sections are a game-changer in construction, offering a blend of strength, lightness, and elegance. These sections are characterized by their Z-shaped cross-section, which imparts them their name. Constructed from aluminum, a material renowned for its strength and recyclability, these sections are both durable and environmentally friendly. Key features include:

- Lightweight and High Strength: Z sections offer a superior strength-to-weight ratio, making them ideal for structures where weight reduction is crucial without compromising strength.

- Corrosion Resistance: The aluminum composition ensures long-lasting durability, even in harsh environmental conditions.

- Versatility: These sections can be used in a variety of applications, from residential buildings to large-scale industrial structures, showcasing their adaptability across different sectors.

Applications of Z Aluminum Sections in Construction: Case StudiesZ aluminum sections have been successfully applied in various construction projects, demonstrating their versatility and effectiveness. Case studies include:

- Residential Projects: In a modern home renovation, Z sections were used for windows and doors, enhancing both the structural integrity and the aesthetic appeal of the home, resulting in a cost-effective and energy-efficient solution.

- Commercial Buildings: A store front underwent a complete overhaul, utilizing Z sections for the exterior framework. This choice not only improved the building's durability but also elevated its visual appeal, attracting more foot traffic.

- Industrial Applications: In a manufacturing plant, Z sections were installed as beams, showcasing their ability to handle heavy loads efficiently, thereby enhancing the plant's structural integrity and operational efficiency.

These case studies highlight how Z sections can be seamlessly integrated into different construction projects, offering a blend of form and function.

Designing for Durability: Key Considerations and PracticesEnsuring the durability of Z aluminum sections involves a combination of material selection, load-bearing capacity, and environmental considerations. Key practices include:

- Material Selection: The thickness of the section plays a crucial role in durability, with thicker sections offering greater resistance to stress and deformation.

- Load-Bearing: Understanding the load-bearing requirements ensures that Z sections are designed to withstand the stresses of daily use, whether in residential or industrial settings.

- Environmental Factors: Proper surface treatments, such as painting or coating, enhance durability by preventing rust and corrosion, even in challenging environments.

Enhancing Aesthetics: Design Techniques and InnovationsAesthetics are a cornerstone of construction projects, and Z aluminum sections offer numerous design possibilities:

- Color Options: A variety of finishes and paints allow for customization, enabling architects to integrate Z sections into diverse design themes.

- Surface Treatments: Innovations like etching, embossing, and anodizing provide additional design opportunities, allowing for unique and modern finishes.

- Innovative Design: The Z shape itself provides versatility, appearing in facades, roofs, and interior features, creating visually striking and functional designs.

Comparison with Traditional Materials: Evaluating Performance and Cost-effectivenessWhen comparing Z aluminum sections with traditional materials like steel and wood, several factors come into play:

- Initial Investment: Z sections may require a higher upfront cost due to the premium of aluminum, though this can be offset by long-term savings.

- Maintenance Costs: Their lower maintenance requirements reduce ongoing costs, making them more economical in the long run.

- Environmental Impact: The aluminum's recyclability contributes to a lower carbon footprint, aligning with sustainability goals.

Future Trends and Innovations in Z Aluminum Section TechnologyThe future of Z aluminum sections is poised for innovation:

- Advancements in Manufacturing: New techniques could enhance the production of Z sections, making them lighter and stronger.

- Material Science Innovations: Custom alloys might offer enhanced strength or lighter weights, expanding their application potential.

- Sustainable Design: The focus on durability and aesthetics will likely drive further integration into green construction projects.

Z aluminum sections represent a significant leap forward in construction materials, offering a perfect balance of strength, durability, and aesthetic appeal. Their versatility across various applications and their potential for future innovation make them an essential component of modern construction. As the demand for sustainable and efficient solutions grows, Z sections are poised to play a central role in shaping the future of architecture and engineering. Encouraging their adoption through education and innovation will ensure their continued evolution in the construction industry.