Why Aluminum Baffles Are Superior for Heat Dissipation

Heat dissipation involves managing the transfer of heat from a hotter object to a cooler one, ensuring systems operate effectively. Aluminum baffles are essential components in heat exchangers, designed to enhance heat transfer by increasing turbulence. These plates, which are placed perpendicularly in fluid channels, disrupt laminar flow, creating turbulence that significantly boosts heat dissipation.

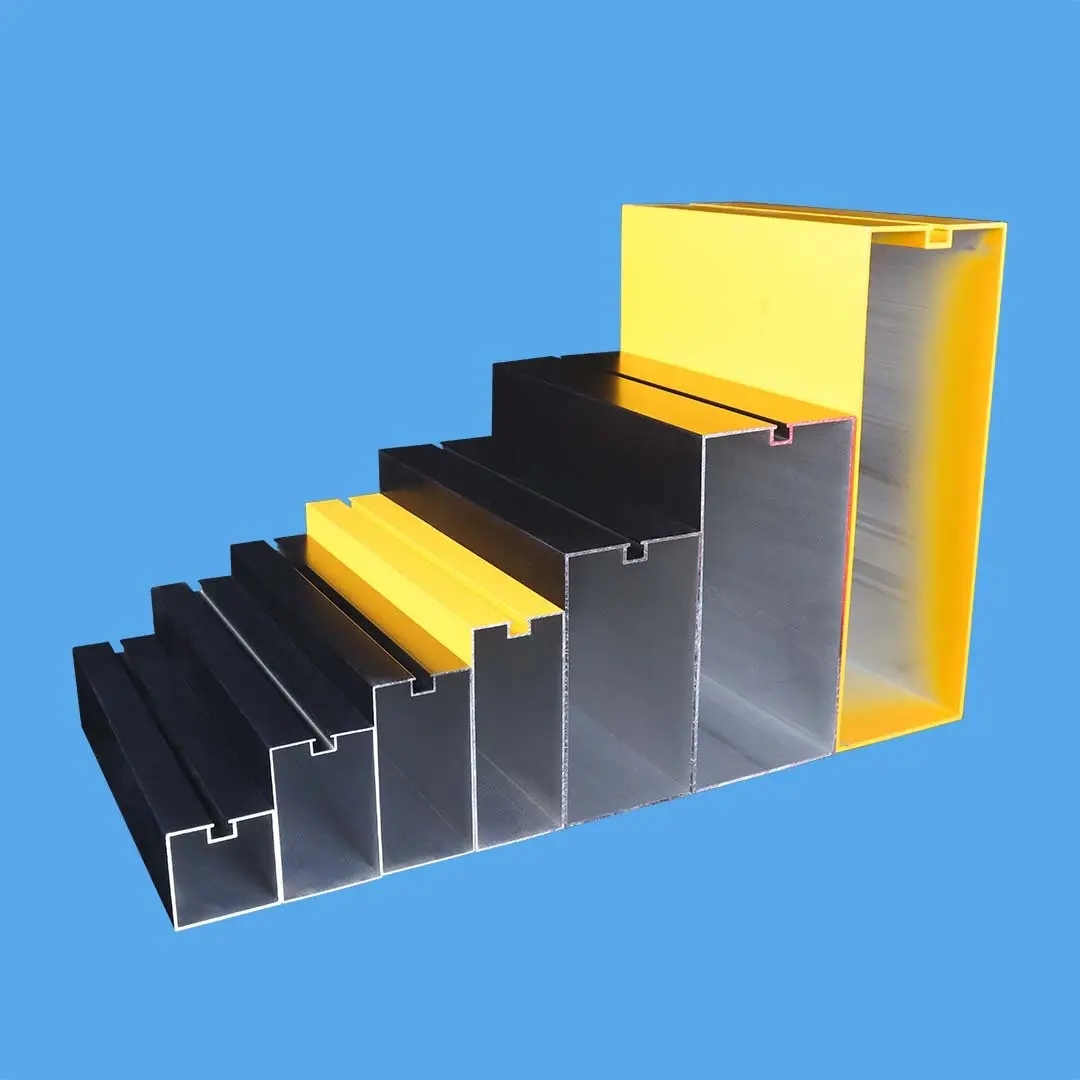

What Are Aluminum Baffles and How Do They Function?

Aluminum baffles are metal plates used to improve heat transfer in fluid channels. These plates are designed to disrupt laminar flow, enhancing turbulence and boosting heat dissipation. This design ensures that the fluid is in constant contact with the metal surface, maximizing heat absorption and ensuring efficient heat transfer.

Key Applications of Aluminum Baffles

Aluminum baffles are crucial in industries where efficient heat management is essential. In the automotive industry, they are used to cool engines, ensuring optimal performance under high temperatures. In electronics, they manage heat in data centers, protecting sensitive components from overheating. HVAC systems benefit from aluminum baffles in adjusting air temperatures efficiently.

For instance, in data centers, aluminum baffles help maintain optimal temperatures, reducing the risk of overheating and extending the lifespan of sensitive components. A recent case study by a major data center operator shows that using aluminum baffles reduced cooling costs by 20% and extended equipment life by 15%.

Comparative Analysis: Performance Metrics of Aluminum Baffles

Real-world examples significantly highlight the performance of aluminum baffles. A study conducted by the National Institute of Standards and Technology (NIST) demonstrated that aluminum baffles outperformed copper baffles by 10% in terms of thermal efficiency. They also required 25% less maintenance over a five-year period, making them cost-effective and durable.

Durability and Cost-Effectiveness

Aluminum baffles are known for their durability. They require minimal maintenance, reducing long-term operational costs. Their lower initial investment and longer lifespan make them a sustainable choice for industries with high heat dissipation needs. Additionally, the environmental benefits of aluminum recycling add to their appeal.

Future Trends in Aluminum Baffle Technology

Emerging trends in aluminum baffle technology include advanced manufacturing processes and integrated cooling solutions. Innovations such as high-temperature resistant aluminum and compact, aerodynamic designs promise even better heat dissipation. For instance, new manufacturing techniques have increased the thermal conductivity of aluminum by up to 15%, making them even more efficient.

Reinforcing the Superiority of Aluminum Baffles

In conclusion, aluminum baffles are a leading choice for heat dissipation, offering exceptional thermal conductivity, durability, and cost-effectiveness. Their versatility across industries underscores their importance in managing temperature efficiently. As technology continues to evolve, aluminum baffles will play an increasingly critical role in heat management and opening new possibilities for innovative solutions.

Aluminum baffles represent a forward-looking solution that can address future challenges in heat management. Anticipating the next generation of advancements, we can anticipate even more efficient and sustainable solutions for heat dissipation. By harnessing the power of aluminum, industries can achieve higher levels of performance while reducing maintenance costs and environmental impact.