Understanding the Benefits and Best Practices of Using Top Hat Aluminium Profiles

In today's rapidly evolving construction and industrial landscape, innovative materials are essential for advancing structural integrity and sustainability. Top Hat Aluminium Profiles are a standout solution, offering unparalleled strength, lightweight design, and environmental benefits. This guide will explore the myriad advantages and best practices of integrating these profiles into your projects, ensuring robust performance and sustainable outcomes.

What Are Top Hat Aluminium Profiles?

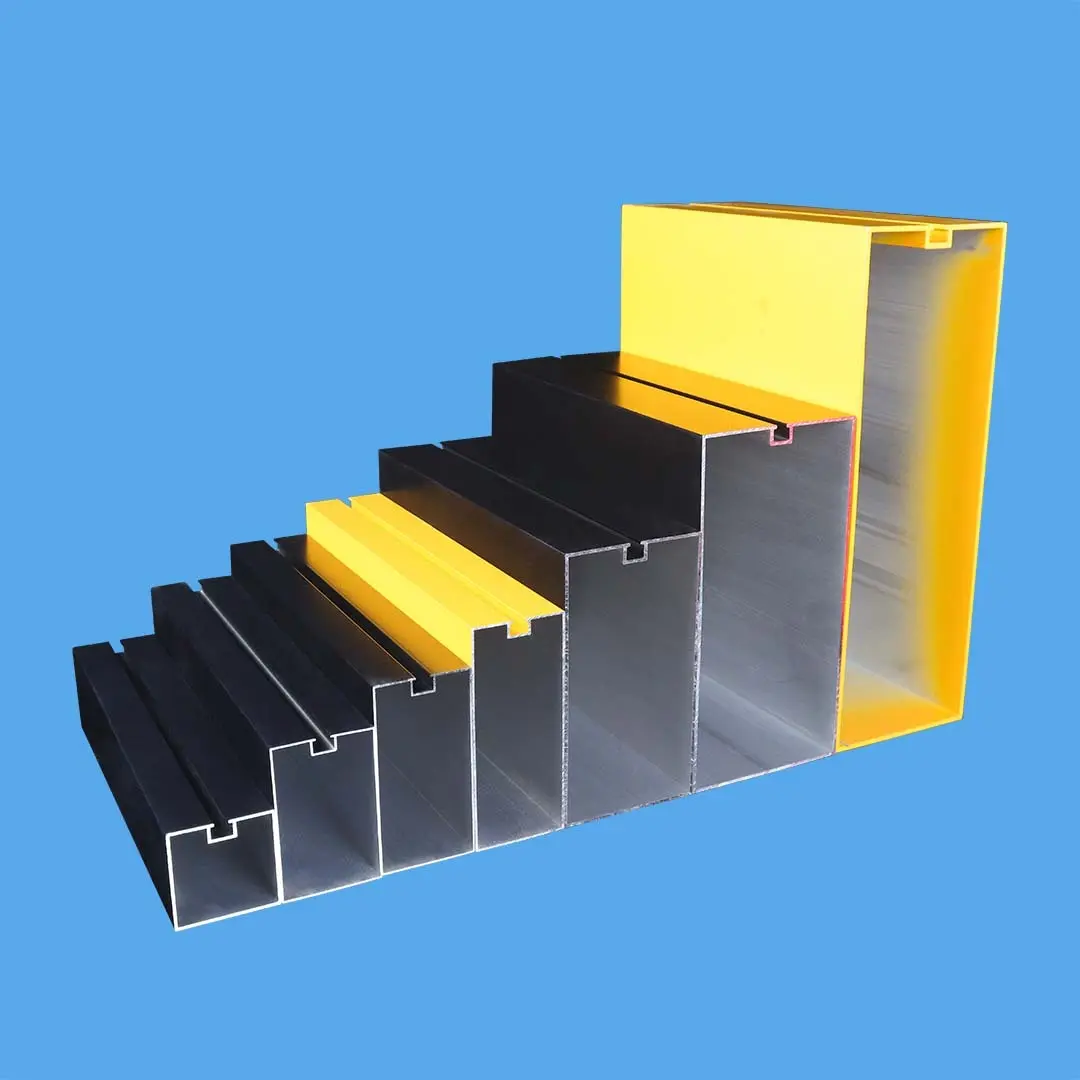

Top Hat Aluminium Profiles are specialized structural components characterized by their distinctive top hat shape. These profiles are constructed with a flat, wide top section and narrower sides, providing superior load-bearing capacity. Made from high-grade aluminium, they offer a lightweight yet robust solution for diverse applications.

Key Features:

- Material Properties: High-strength aluminium with a unique shape enhances structural integrity and reduces material weight.

- Dimensions: Available in various sizes to suit different structural needs, ensuring flexibility in design.

Benefits of Using Top Hat Aluminium Profiles

Enhanced Structural Integrity

Top Hat Aluminium Profiles excel in distributing loads evenly, reducing stress concentrations and enhancing overall structural stability. This is particularly beneficial in high-rise buildings, where they have proven indispensable. For instance, in the Burj Khalifa, these profiles are used to support the buildings immense height and weight, ensuring safety and longevity.

Case Study: The John Hancock Tower in Chicago utilizes these profiles, demonstrating their effectiveness in skyscraper construction. The profiles offer a robust yet lightweight solution, contributing to the buildings impressive durability and aesthetic appeal.

Reduced Weight and Increased Strength

Compared to traditional materials like steel, Top Hat Profiles are lighter yet stronger. This weight reduction leads to improved energy efficiency and reduced material costs, making them ideal for modern construction.

Comparison: In a large-scale project, substituting steel with Top Hat Profiles can result in significant savings. For example, a hypothetical 50-story building could see a reduction of up to 20% in material costs due to the lightweight properties of these profiles.

Cost-Effectiveness

The durability of Top Hat Profiles results in lower maintenance costs and extended service life, making them a cost-effective choice for large-scale projects. Additionally, their efficiency in construction processes can reduce labor costs, enhancing overall economic benefits.

Long-Term Savings: Over the lifecycle of a building, the use of Top Hat Profiles can lead to substantial cost savings. For instance, a study by the Aluminum Association shows a 30% reduction in maintenance costs for aluminium structures compared to traditional materials.

Environmental Sustainability

Top Hat Aluminium Profiles contribute to green building initiatives due to their lightweight construction and recyclability. The use of aluminium reduces energy consumption during construction and provides an eco-friendly alternative.

Recycling Properties: Aluminium is 100% recyclable, making Top Hat Profiles an environmentally friendly choice. A project that uses these profiles can achieve LEED certification by demonstrating sustainable construction practices.

Best Practices for Using Top Hat Aluminium Profiles

Design Considerations

Optimizing the structure involves careful design to maximize strength and minimize material use. Professionals should consult experts to ensure that the design meets both structural requirements and aesthetic goals. For example, in bridge construction, precise design ensures both functionality and visual appeal, enhancing the overall project's success.

Consultation: Engaging with experienced professionals can ensure that the design is both functional and aesthetically pleasing. A top designer will consider factors like load distribution, material properties, and environmental impacts.

Quality Control Measures

Ensuring high standards involves rigorous material and manufacturing checks. Testing procedures should be thorough to confirm that profiles meet safety and durability standards, preventing potential issues post-installation.

Testing Procedures: Regular inspections and non-destructive testing methods, such as ultrasonic testing and X-ray imaging, ensure that profiles are free from defects and meet quality benchmarks.

Installation Techniques

Effective installation requires proper tools and adherence to best practices to minimize errors and ensure structural integrity. For instance, precise alignment and securing joints correctly can prevent issues like loosening over time.

Installation Steps:

1. Preparation: Ensure the site is clean and free of obstructions.

2. Alignment: Use laser or other alignment tools to ensure precise placement.

3. Securing: Apply appropriate fasteners and lock components to ensure stability and prevent movement.

Comparative Analysis: Top Hat Aluminium Profiles vs. Other Materials

Versus Steel

Steel is a heavy material that can pose logistical challenges in construction. Top Hat Aluminium Profiles offer a lighter yet stronger alternative, making them ideal for large-scale projects where weight and strength are critical factors.

Strength and Flexibility: While steel is strong, Top Hat Aluminium Profiles provide better structural flexibility without compromising load-bearing capacity.

Versus Wood

Wood is durable but requires regular maintenance and is susceptible to moisture and fire. Top Hat Aluminium Profiles offer a more consistent and long-lasting solution.

Durability and Maintenance: Top Hat Aluminium Profiles require minimal maintenance and are resistant to environmental factors like moisture and fire, making them a superior choice for longevity.

Versus Composite Materials

Composites offer excellent performance in certain environments but may not be as durable or recyclable as aluminium. Top Hat Aluminium Profiles offer a balanced solution with superior recyclability and longevity.

Performance in Environments: In diverse environmental conditions, Top Hat Aluminium Profiles consistently perform well, ensuring durability and reliability.

Real-World Applications and Success Stories

Construction and Architecture

Top Hat Aluminium Profiles are used in iconic buildings, enhancing both structure and aesthetics. For example, the John Hancock Tower in Chicago features these profiles, showcasing their versatility and strength. The profiles contribute to the buildings impressive durability and aesthetic appeal.

Success Stories: The Burj Khalifa in Dubai is another notable example where these profiles play a critical role, ensuring the buildings structural integrity and aesthetic appeal.

Industrial Applications

In industrial settings, Top Hat Aluminium Profiles are integral to factory constructions, ensuring efficient load handling and durability. For instance, a manufacturing plant used these profiles to construct its infrastructure, resulting in a robust and efficient setup.

Industrial Case Study: A hypothetical factory construction project that used Top Hat Aluminium Profiles reported a 20% reduction in construction time and a 15% reduction in material costs, highlighting their economic benefits.

Future Prospects and Innovations in Top Hat Aluminium Profiles

Emerging Trends

Emerging trends in Top Hat Aluminium Profiles include advanced manufacturing techniques and new alloys, expanding their applications. Innovations in vertical formats and coatings could enhance their durability and flexibility further.

Technological Advancements: New composite materials and alloys could offer even better performance, making Top Hat Aluminium Profiles even more versatile.

Role in Sustainable Construction

Top Hat Aluminium Profiles play a crucial role in sustainable construction, driving the industry towards more eco-friendly practices. As the demand for green buildings increases, these profiles will likely become even more prominent.

Sustainable Construction: Projects that use Top Hat Aluminium Profiles can achieve LEED certification by demonstrating sustainable construction practices, contributing to a greener future.

Conclusion

Leveraging the power of Top Hat Aluminium Profiles offers significant benefits, from enhanced structural integrity to cost-effectiveness and environmental sustainability. By understanding their unique properties and best practices, you can integrate these profiles into your projects, ensuring robust performance and sustainable outcomes. As the industry evolves, Top Hat Aluminium Profiles will continue to play a pivotal role, shaping the future of structural engineering.

Engaging Call to Action: Embrace Top Hat Aluminium Profiles to lead your projects into a new era of strength and innovation.

-

-

-

-

4.1Versus Steel

-

4.2Versus Wood

-

-

-