Aluminium Square Tube: The Future of Lightweight Structural Solutions

The transition towards sustainable and efficient construction practices has driven the need for lightweight materials that can replace traditional heavier ones without compromising performance. In industries such as architecture, aerospace, automotive, and civil engineering, weight reduction is not only a matter of cost but also a necessity for improving energy efficiency, reducing environmental impact, and enhancing safety. Traditional materials like steel and concrete, while robust, often require significant resources to produce and have a substantial carbon footprint. In contrast, lightweight materials like aluminium square tubes offer a compelling alternative, providing the strength and durability required for structural applications while significantly reducing weight.

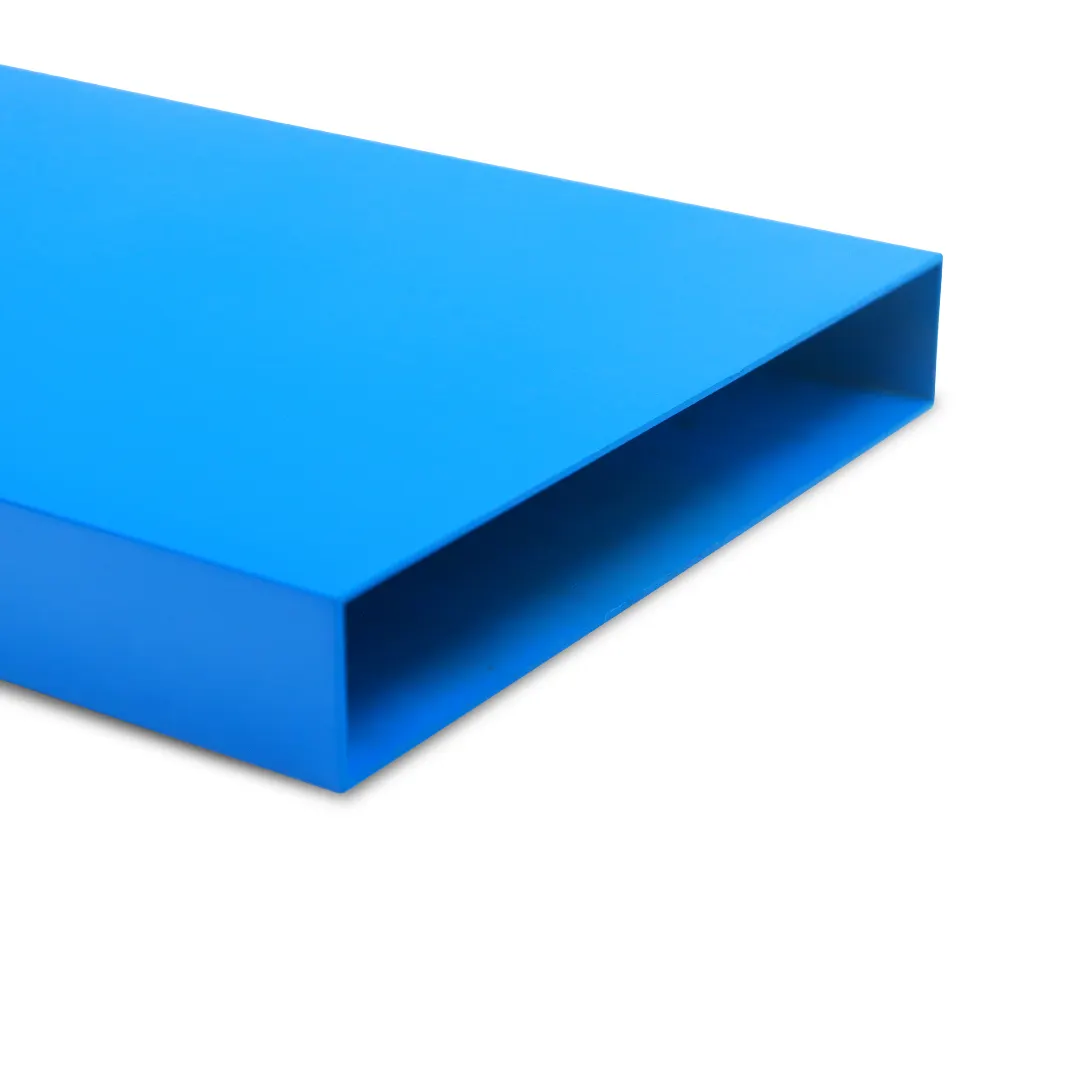

Aluminium square tubes, also known as rectangular tubes, are hollow structural sections made from aluminium, a material that is lightweight, corrosion-resistant, and highly durable. These tubes are widely used in construction, manufacturing, and engineering due to their ability to span long distances while supporting heavy loads. Their versatility allows them to be used in a wide range of applications, from building frameworks to mechanical components. As industries continue to seek innovative solutions to reduce weight and improve performance, aluminium square tubes are becoming an essential part of the structural toolkit.

Structural Advantages of Aluminium Square Tubes

One of the most significant advantages of aluminium square tubes is their strength-to-weight ratio, which makes them ideal for applications where weight reduction is critical. Compared to traditional materials like steel, aluminium square tubes are approximately 40% lighter while maintaining the same strength, making them a more efficient choice for structural applications. This property is particularly beneficial in industries where weight savings can lead to significant energy savings, such as in the automotive and aerospace industries.

Another key advantage of aluminium square tubes is their durability and resistance to corrosion. aluminium is inherently resistant to weathering and oxidation, making these tubes a long-lasting option for outdoor and indoor structures. Unlike steel, which can rust and require regular maintenance, aluminium square tubes are maintenance-free, reducing the need for costly repairs and extending the lifespan of a project.

The corrosion resistance of aluminium square tubes is further enhanced by their hollow structure, which allows for a thick wall that can withstand harsh environments. This makes them ideal for use in industrial settings, where they are exposed to high temperatures, humidity, and corrosive substances.

In addition to their strength and durability, aluminium square tubes are also easier to fabricate and install than many traditional materials. Their rectangular shape allows for precise fitting and alignment, making them ideal for complex structural designs. Furthermore, aluminium square tubes are highly resistant to fire and can be used in high-temperature applications, adding to their versatility.

Innovative Applications in the Automotive Industry

The automotive industry is one of the most prominent users of aluminium square tubes, as they play a critical role in reducing the weight of vehicles while maintaining safety and performance. Lightweight components are essential in the automotive industry, where every gram saved can improve fuel efficiency and reduce emissions. aluminium square tubes are commonly used in vehicle frames, engine mounts, and suspension systems, where their strength and durability are crucial.

For example, the frame structure of modern cars is often built using aluminium square tubes, which provide the necessary strength to withstand the stresses of driving while keeping the overall weight low. These tubes are also used in engine mounts, where they help to isolate vibrations and reduce noise, improving the overall driving experience. In addition, aluminium square tubes are used in the suspension system, where they provide stability and reduce wear and tear on other components.

One notable case study is the use of aluminium square tubes in the lightweight frame of a high-performance sports car. By replacing traditional steel components with aluminium square tubes, the car's weight was reduced by 15%, resulting in improved fuel efficiency and reduced emissions. This approach not only enhances the vehicle's performance but also aligns with global efforts to reduce carbon emissions and promote sustainable transportation.

Architectural Innovations with Aluminium Square Tubes

Aluminium square tubes have also found innovative applications in the field of architecture, where they are used to create lightweight and visually striking structures. architects are increasingly turning to aluminium square tubes for their aesthetic and functional versatility, as they offer a way to incorporate weight-saving measures without compromising on design.

One of the key advantages of aluminium square tubes in architecture is their ability to create open, light-filled spaces while maintaining structural integrity. For example, in the design of lightweight frameworks for building roofs and floors, aluminium square tubes are used to create a grid system that allows for maximum flexibility and minimal material usage. This approach not only reduces the overall weight of the structure but also enhances its thermal performance, making it more energy-efficient.

Another example is the use of aluminium square tubes in the design of decorative elements, such as columns and structural supports. These tubes can be combined with other materials, such as glass or composite panels, to create visually stunning and structurally sound designs. The hollow structure of aluminium square tubes allows for the incorporation of intricate detailing, making them ideal for creating architectural elements that are both functional and aesthetically pleasing.

In addition to their use in construction, aluminium square tubes are also used in the design of bridges, towers, and other large-scale structures. Their lightweight and durable properties make them an ideal choice for projects where both strength and sustainability are critical. For instance, the use of aluminium square tubes in the construction of a suspension bridge allows for a more slender and efficient design, reducing the overall footprint while maximizing the span.

Comparative Analysis: Cost, Manufacturing, and Maintenance

When evaluating the use of aluminium square tubes, it is important to consider not only their structural advantages but also their cost, manufacturing processes, and maintenance requirements. While aluminium square tubes may require a higher initial investment, they offer long-term savings in terms of weight reduction, energy consumption, and reduced maintenance costs.

The cost of aluminium square tubes depends on factors such as the size, thickness, and length of the tubes, as well as the complexity of the manufacturing process. Compared to traditional materials like steel, aluminium square tubes are generally more expensive to produce, but this cost is offset by the long-term benefits of reduced weight and energy savings. Additionally, the corrosion resistance and durability of aluminium square tubes make them a more reliable option in the long run, reducing the need for frequent repairs and replacements.

The manufacturing process for aluminium square tubes involves rolling and shaping raw aluminium into the desired shape, followed by heat treatment and surface finishing. While this process is more complex than that of traditional materials, it allows for the production of customised sizes and shapes, giving manufacturers greater flexibility to meet specific project requirements.

Maintenance of aluminium square tubes is relatively simple, as they are maintenance-free due to their corrosion resistance. Unlike steel or concrete, which require regular painting, coating, or repair, aluminium square tubes can be cleaned and maintained without any special machinery. This makes them an ideal choice for applications where ease of maintenance is a priority.

Future Trends and Technological Advancements

The future of aluminium square tubes is looking bright, with several emerging trends and technological advancements on the horizon. As industries continue to demand lightweight and sustainable solutions, aluminium square tubes are expected to play an increasingly important role in shaping the next generation of construction and engineering projects.

One of the most promising areas of innovation is the development of advanced manufacturing techniques, such as additive manufacturing (3D printing) and precision engineering. These technologies allow for the creation of customised aluminium square tubes with greater accuracy and efficiency, enabling architects and engineers to design structures with unprecedented precision. Additive manufacturing, in particular, offers the potential to create complex shapes and structures that were previously impossible to produce using traditional methods.

Another exciting development is the use of aluminium square tubes in new and unconventional applications. For example, researchers are exploring the use of these tubes in the development of lightweight robot arms, modular furniture, and even consumer electronics like smartphones and laptops. The versatility and strength of aluminium square tubes make them an ideal choice for a wide range of applications, from industrial automation to everyday consumer products.

In addition to these technological advancements, the environmental benefits of aluminium square tubes are also expected to grow. As industries continue to prioritise sustainability, aluminium square tubes are well-positioned to play a key role in reducing carbon emissions and promoting a greener economy. The use of recycled aluminium in the production process, for example, can help to reduce the environmental impact of these tubes while maintaining their high strength and durability.

The Promise of Lightweight Solutions with Aluminium Square Tubes

Aluminium square tubes are at the forefront of the lightweight structural solutions revolution, offering a unique combination of strength, durability, and versatility that makes them an essential tool for modern engineering and construction. Their ability to reduce weight while maintaining structural integrity has made them a popular choice in industries such as automotive, aerospace, and architecture, where efficiency and sustainability are critical.

As industries continue to demand innovative and sustainable solutions, aluminium square tubes are expected to play an increasingly important role in shaping the future of lightweight structural design. With advancements in manufacturing techniques, new applications in emerging fields, and a growing emphasis on environmental sustainability, aluminium square tubes are poised to become a cornerstone of the next generation of construction and engineering projects.

In conclusion, aluminium square tubes are not just a material; they are a symbol of the potential for lightweight solutions to transform the way we build and engineer the world. By embracing the advantages of aluminium square tubes, industries can achieve greater efficiency, reduce their environmental impact, and create innovative and sustainable solutions for the future.